- Home

- About Vidatech

- Filament Winding Machine

- Multi-axis Filament Winding Machine-Wet

- Prepreg Tape Filament Winding Machine -Dry

- GRP pipe Continuous Filament Winding production line

- GRP pipe Discontinuous Filament Winding Machine

- FRP Vertical Tank Filament Winding Machine

- FRP Horizontal tank Filament Winding Machine

- FRP Pole (conic pole) Machine

- GRP Production Know-How

- GRP Production Others

- GRP Laboratory Testing Equipment

- FRP Project and Engineering

- Raw Materials Department

- Project Gallary

- news

- Contact Details

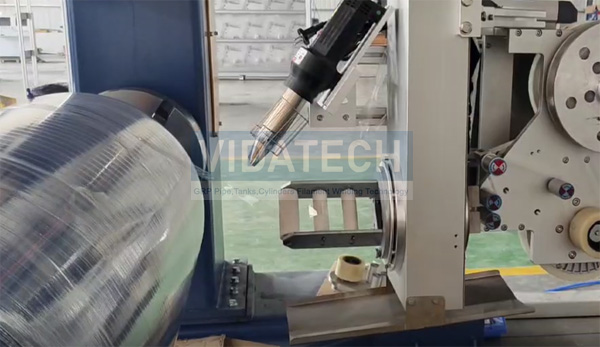

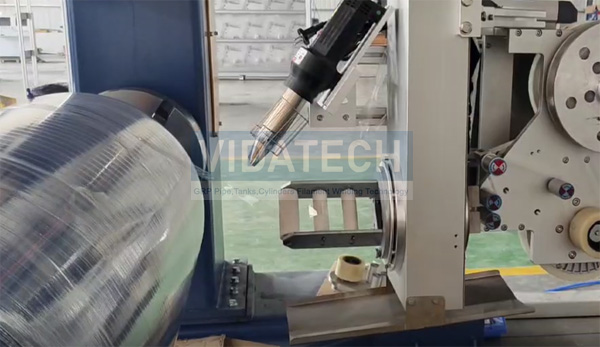

Prepreg Tape Filament Winding Machine -Dry

Prepreg Tape Filament Winding Machine -Dry winding

The dry winding system is via high-precision control system to feed the fiber-tow or tape-creel into a head-heater-device,before apply on the mandrel/ inner cylinder/ mold,the material s will be heated to "softened state", then quickly filament-wound on .

The materials covers two types, thermosetting and themoplastic The heater type including hot melting,IR(Infrared) ,Laser etc.

Product Part diameter: DN50-DN2000mm(Thermosetting)

Vessel maximum length: 6000mm

Fiber tension control system:High precision adjustment 1-20N

Temperature:180-250℃

Tape Widths: 50mm (2”), 75mm (3”)

Speed:1.2m/60s

Electric Control System: CNC control system

With filament winding Software

Application:

1. automotive parts

2. Carbon fiber vessels

3. Fiberglass tubes,Carbon tubes

Advantage

1. Without resin bath, more cleaning working enviorment

2. The products pars are with more hihg precision contenting of the resin materials,

so enable to control the qaulity like uniform vessel-wall,high accuracy,uniform tension.

3.High prodcution efficiency.

The dry winding system is via high-precision control system to feed the fiber-tow or tape-creel into a head-heater-device,before apply on the mandrel/ inner cylinder/ mold,the material s will be heated to "softened state", then quickly filament-wound on .

The materials covers two types, thermosetting and themoplastic The heater type including hot melting,IR(Infrared) ,Laser etc.

Product Part diameter: DN50-DN2000mm(Thermosetting)

Vessel maximum length: 6000mm

Fiber tension control system:High precision adjustment 1-20N

Temperature:180-250℃

Tape Widths: 50mm (2”), 75mm (3”)

Speed:1.2m/60s

Electric Control System: CNC control system

With filament winding Software

Application:

1. automotive parts

2. Carbon fiber vessels

3. Fiberglass tubes,Carbon tubes

Advantage

1. Without resin bath, more cleaning working enviorment

2. The products pars are with more hihg precision contenting of the resin materials,

so enable to control the qaulity like uniform vessel-wall,high accuracy,uniform tension.

3.High prodcution efficiency.