- Home

- About Vidatech

- Filament Winding Machine

- Multi-axis Filament Winding Machine-Wet

- Pregreg Tape Filament Winding Machine -Dry

- GRP pipe Continuous Filament Winding production line

- GRP pipe Discontinuous Filament Winding Machine

- FRP Vertical Tank Filament Winding Machine

- FRP Horizontal tank Filament Winding Machine

- FRP Pole (conic pole) Machine

- GRP Production Others

- GRP Laboratory Testing Equipment

- GRP Production Know-How

- Raw Materials Department

- Project Gallary

- news

- Contact Details

HDB Long-Term Testing Machine

HDB Long-Term Static Hydrostatic Test Systems for GRP pipe, GRE pipe .

General description:

One of the main data of GRP pipes design is based on the materials of inner layer and structure layer’s pressure performance during different time. Long-term performance of GRP pipe, under the condition of meeting certain requirements, can ensure safe and reliable using within the designed lifetime Vidatech introduce HDB testing equipment production technology and measurements techniques, which used in AMIANTIT, FPI etc. According to ASTM standard, within 10000 hours, with maximum 18pcs standard specimens, then the testing result evaluated and obtain the value of 50 years.

Testing equipment consists of by:

- Mobile pressure device ;

- temperature control heating enclosures ;

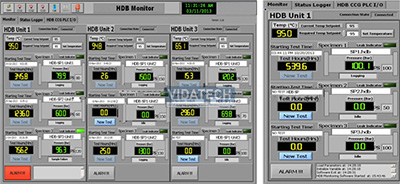

- computer control devices for process control , monitoring, reporting

Standard:

Test procedure according to DIN BS EN 1447, ASTM D 2992 and ASTM D 1598

Advantage:

•Several tests to proceed at the same time. The user can define the pressure, temperature and testing time, the testing and monitoring is automatically and continuously. Each specific piping product is under independent environmental conditions, not be affected each others. After testing finish, the equipment could be detected automatically. Each specimen failure measured by independent failure alarm device.

•The monitoring can be done from the Laboratory’s computer, or from the site’s control units equipped on the enclosure. The reports generated are compatible with Windows office.

•Results of Each test specimen are integrated and displayed on a log-log graph, easy for analysis.

•Test procedure according to DIN BS EN 1447, ASTM D 2992 and ASTM D 1598

General description:

One of the main data of GRP pipes design is based on the materials of inner layer and structure layer’s pressure performance during different time. Long-term performance of GRP pipe, under the condition of meeting certain requirements, can ensure safe and reliable using within the designed lifetime Vidatech introduce HDB testing equipment production technology and measurements techniques, which used in AMIANTIT, FPI etc. According to ASTM standard, within 10000 hours, with maximum 18pcs standard specimens, then the testing result evaluated and obtain the value of 50 years.

Testing equipment consists of by:

- Mobile pressure device ;

- temperature control heating enclosures ;

- computer control devices for process control , monitoring, reporting

Standard:

Test procedure according to DIN BS EN 1447, ASTM D 2992 and ASTM D 1598

Advantage:

•Several tests to proceed at the same time. The user can define the pressure, temperature and testing time, the testing and monitoring is automatically and continuously. Each specific piping product is under independent environmental conditions, not be affected each others. After testing finish, the equipment could be detected automatically. Each specimen failure measured by independent failure alarm device.

•The monitoring can be done from the Laboratory’s computer, or from the site’s control units equipped on the enclosure. The reports generated are compatible with Windows office.

•Results of Each test specimen are integrated and displayed on a log-log graph, easy for analysis.

•Test procedure according to DIN BS EN 1447, ASTM D 2992 and ASTM D 1598