- Home

- About Vidatech

- Filament Winding Machine

- Multi-axis Filament Winding Machine-Wet

- Pregreg Tape Filament Winding Machine -Dry

- GRP pipe Continuous Filament Winding production line

- GRP pipe Discontinuous Filament Winding Machine

- FRP Vertical Tank Filament Winding Machine

- FRP Horizontal tank Filament Winding Machine

- FRP Pole (conic pole) Machine

- GRP Production Others

- GRP Laboratory Testing Equipment

- GRP Production Know-How

- Raw Materials Department

- Project Gallary

- news

- Contact Details

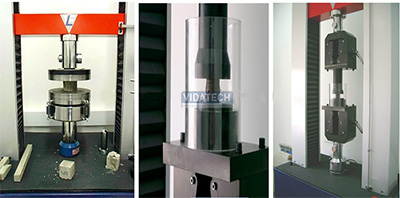

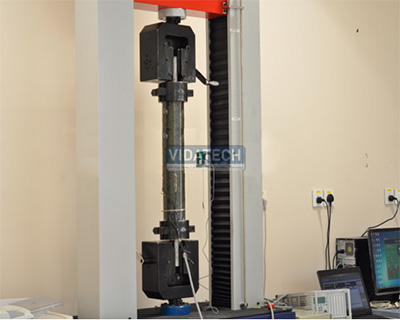

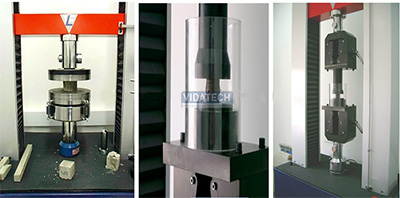

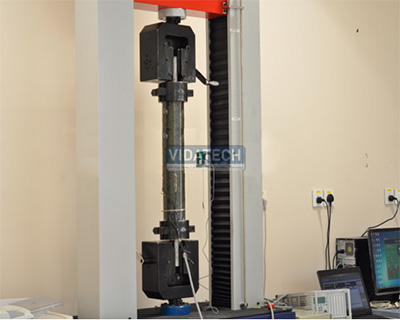

Universal Testing Machine(UTM)

Electronic Universal Testing Machine for GRP pipes

Test Function Scope:

Hoop

Axial

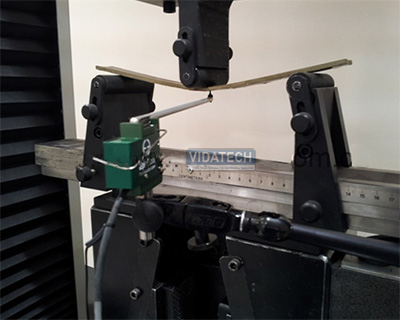

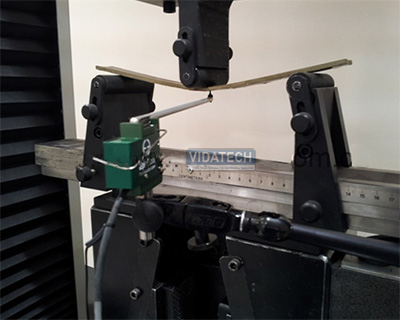

Flexural

Stiffness

Compression

General description:

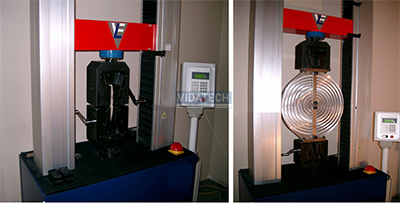

1. Hoop tensile strength testing

Testing method: Split Disc Type and Short Strip Test

1).Split Disc Testing:

With wedge grips, specimens diameter up to DN 450mm, suitable for continuous pipe and discontinuous pipe.

Test procedure according to ISO8521 -B, EN1394-B, ASTM D2290

2).Short Strip Testing:

For testing DN ≥500mm GRP pipe, suitable for continuous pipe and discontinuous pipe’s apparent circumferential strength.

Test procedure according to ISO8521 -D, EN1394-D.

2. Axial testing

Specimens diameter DN100mm.

Test procedure according to ASTM D2105.

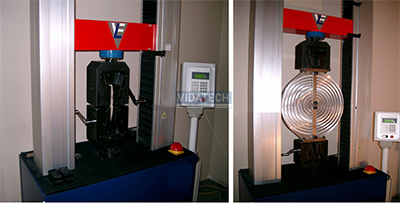

3. Stiffness testing

For testing GRP pipe ring stiffness with monitor graph and report.

Test procedure according to ISO7685, ASTM D2412.

4. Compression testing

Compression capacity 15ton(150KN).

Test procedure according to ASTM D 695.

Advantage:

All the testing data, even performed by different testing machine, can be integrated together in to one database system. Powerful data mining and analysis function,

Test Function Scope:

Hoop

Axial

Flexural

Stiffness

Compression

General description:

1. Hoop tensile strength testing

Testing method: Split Disc Type and Short Strip Test

1).Split Disc Testing:

With wedge grips, specimens diameter up to DN 450mm, suitable for continuous pipe and discontinuous pipe.

Test procedure according to ISO8521 -B, EN1394-B, ASTM D2290

2).Short Strip Testing:

For testing DN ≥500mm GRP pipe, suitable for continuous pipe and discontinuous pipe’s apparent circumferential strength.

Test procedure according to ISO8521 -D, EN1394-D.

2. Axial testing

Specimens diameter DN100mm.

Test procedure according to ASTM D2105.

3. Stiffness testing

For testing GRP pipe ring stiffness with monitor graph and report.

Test procedure according to ISO7685, ASTM D2412.

4. Compression testing

Compression capacity 15ton(150KN).

Test procedure according to ASTM D 695.

Advantage:

All the testing data, even performed by different testing machine, can be integrated together in to one database system. Powerful data mining and analysis function,