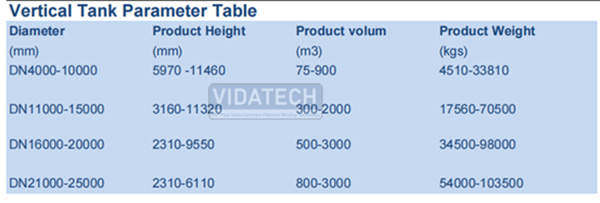

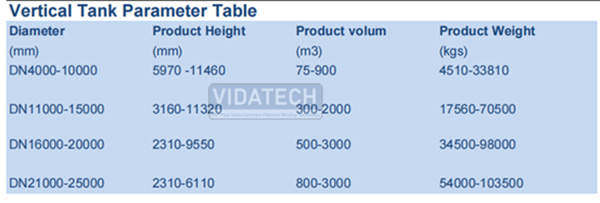

GRP FRP Fiberglass Vertical Tank

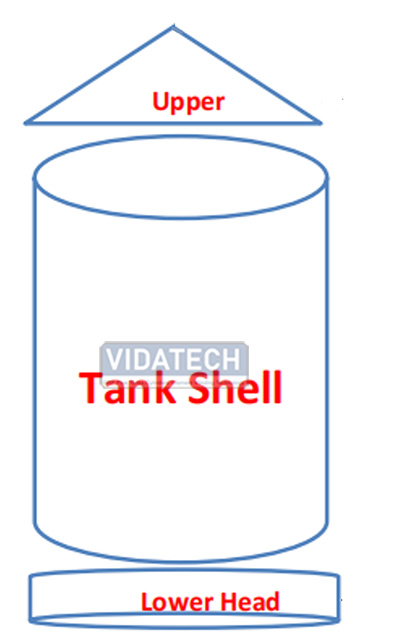

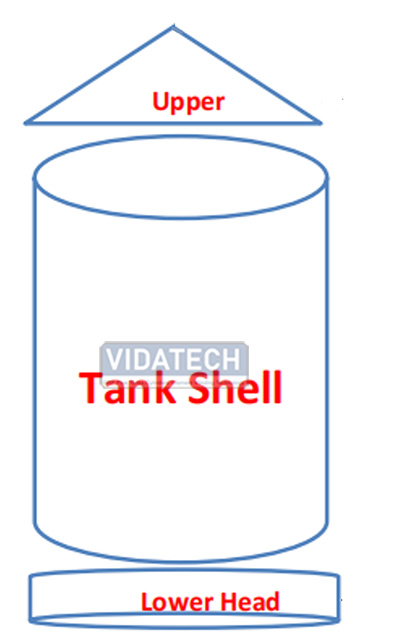

The tanks is with inner layer for acid and alkali resistance, leakage prevention and structural layer for reinforcement, and external gelcoat for UV and surface good looking.

After finishing production, an inspection is necessary.

GRP FRP Fiberglass tank provides an excellent performance solution for upground or underground storage vessels.

The application is various and wide, water treatment, chemical liquid storage, steel pickling, chlorine, semiconductor industry, fertiliser, edible soy sauce, detergent etc.

Vidatech provide Engineering based on Filament Winding Processing, including

the filament winding machine, technicians, workers, also the FRP tank constructions drawings, production processing design, and recommend production using raw materials

After finishing production, an inspection is necessary.

GRP FRP Fiberglass tank provides an excellent performance solution for upground or underground storage vessels.

The application is various and wide, water treatment, chemical liquid storage, steel pickling, chlorine, semiconductor industry, fertiliser, edible soy sauce, detergent etc.

Vidatech provide Engineering based on Filament Winding Processing, including

the filament winding machine, technicians, workers, also the FRP tank constructions drawings, production processing design, and recommend production using raw materials

General Description

This filament winding machine is specially design for large scale vertical type FRP tank. Single unit machine.

Application:

1. widely used in the chemical industry

2. Hydrochloric acid storage

3. municipal waste water treatment and water treatment

4. Drinking Water storage

5. Sewage water storage

6. in air pollution control equipment

7. food processing

8. silo storage for grain

Standard:

1. ASTM D3299-88 for filament winding glass fiber reinforced thermosetting resin chemical resistant tank

2. HG T20696-1999 for FRP equipment design for chemical industry.

Advantage:

1. One unit machine, easy installation.

2. Easy and convenient operation, and computer control system.

3. Keep low consumption of the raw materials.

4. Experienced tank production technology assistant.